In today’s world focused on energy conservation it is essential to balance efficiency and cost effectiveness. The differential pressure sensor plays a role, in achieving this equilibrium by measuring pressure variances between two points. This technology is vital for streamlining processes in industries ensuring optimal system performance for energy savings and sustainability. Embracing tools like the pressure sensor and its counterpart, the pressure transmitter empowers businesses and individuals to minimize energy usage and environmental impact.

This piece will delve into the workings of pressure sensors discussing their functionality, operational principles and their significant contribution to improving energy efficiency. After explaining how these sensors function we will explore their applications in industries prioritizing energy conservation. Additionally we will examine the advantages of incorporating these sensors into energy management strategies to help readers understand their role, in reducing both energy costs and carbon emissions.

Finally you’ll receive advice, on choosing and using the differential pressure sensor or transmitter, for your requirements. This will help ensure that you have the information to make use of this technology. By delving into this topic the article aims to demonstrate the role that differential pressure sensors play in advancing towards an efficient and sustainable future.

Understanding Differential Pressure Sensors

Differential pressure sensors gauge the variation, in pressure between two points usually placed on ends of a diaphragm. This assessment plays a role in applications that require monitoring of pressure like, in fluid dynamics or air pressure setups.

How They Work

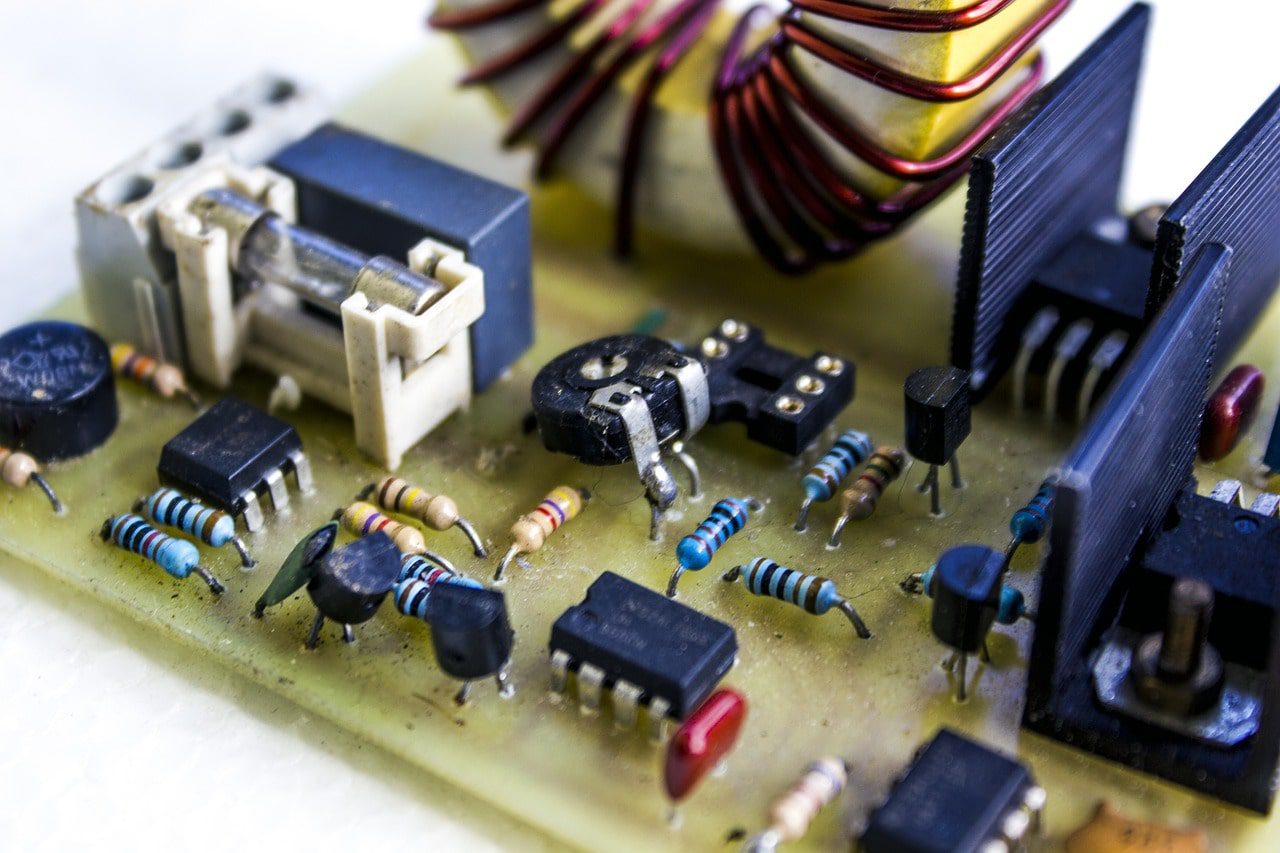

The sensors operate by deflecting a diaphragm in response, to varying pressures. Advanced versions incorporate two sensors with internal electronics for computing and transmitting pressure differentials. Certain configurations feature components and Wheatstone bridge circuits that need signal conditioning to enhance the output for use, in measurement systems or microcontrollers.

Applications of Differential Pressure Sensors in Energy Efficiency

Differential pressure sensors play a role, in HVAC systems by helping to uphold energy efficiency standards. These sensors are responsible for monitoring flow rates and pressures to ensure that systems comply with energy regulations. They regulate air volume. Adjust damper positions to enhance ventilation and minimize energy expenses. Additionally they prompt alerts, for replacing filters, which helps in sustaining system efficiency and maintaining air quality.

Hydroelectric Power Plants

Hydroelectric power stations make use of differential pressure sensors to keep an eye, on water intake and filter status, which is essential for safeguarding turbines and optimizing their performance. In places where technologies like the SP007 model are in place these sensors identify clogs in filters signaling the need for upkeep to avoid turbine harm and improve effectiveness. Their sturdy construction guarantees durability and efficiency over time in environments making a meaningful contribution, to eco-friendly energy methods.

Benefits of Using Differential Pressure Sensors for Energy Efficiency

Differential pressure sensors allow for monitoring systems in real-time offering data to support timely decision making. This continuous flow of information enables adjustments to maintain environments within conditions ultimately minimizing the potential, for energy waste.

Improved System Maintenance

By continuously monitoring pressure levels, differential pressure sensors help predict maintenance needs before they escalate into costly repairs. This proactive approach not only enhances system reliability but also extends the lifespan of HVAC equipment, contributing to overall energy efficiency.

Cost Savings

Implementing differential pressure sensors leads to significant cost savings by optimizing energy use. Accurate and reliable sensors ensure systems operate efficiently, minimizing unnecessary energy expenditure and reducing operational costs over time. This makes them an invaluable tool in energy management strategies.

How to Choose and Implement Differential Pressure Sensors

When selecting a differential pressure sensor, consider the application and the types of fluids involved. For dry gases, the sensor should be mounted above the pipe to allow condensation to drain. For liquids, it should be below to keep the line filled. For condensing steam, ensure a consistent water column is maintained to protect the sensor from high temperatures.

Installation Tips

Proper installation is crucial for sensor performance. Install the sensor vertically with air inlets perpendicular to the ground and ensure all connections are secure. Avoid exposure to direct drafts during installation.

Maintenance Best Practices

Regular maintenance extends sensor life and ensures accuracy. Inspect the sensor for damage and corrosion, ensure tight connections, and clean regularly using mild agents. Calibration is necessary to maintain precision, involving comparison to a known standard and adjustment as needed.

Conclusion

Throughout our exploration we have uncovered the role that differential pressure sensors play in improving energy efficiency across applications. These sensors are essential, for measuring pressure differences needed for optimizing systems in industries such as HVAC and hydroelectric power generation. They are components in promoting sustainability and reducing costs. Embracing technologies is vital for reducing energy consumption minimizing impact and ensuring systems operate at their peak efficiency.

Upon reflecting on the information presented it is evident that differential pressure sensors serve as more than tools; they are partners in the ongoing pursuit of balancing energy efficiency with operational needs. By assisting users in selecting and implementing the sensors for their requirements this article aims to empower individuals and businesses to make informed choices that result in improved energy utilization, cost effectiveness and a smaller ecological footprint. Adopting pressure sensors represents not a technical advancement but also a strategic step toward a greener and more efficient future. This underscores the role of these tools, in our endeavors to conserve energy and safeguard our environment.

certainly like your website but you need to take a look at the spelling on quite a few of your posts Many of them are rife with spelling problems and I find it very troublesome to inform the reality nevertheless I will definitely come back again