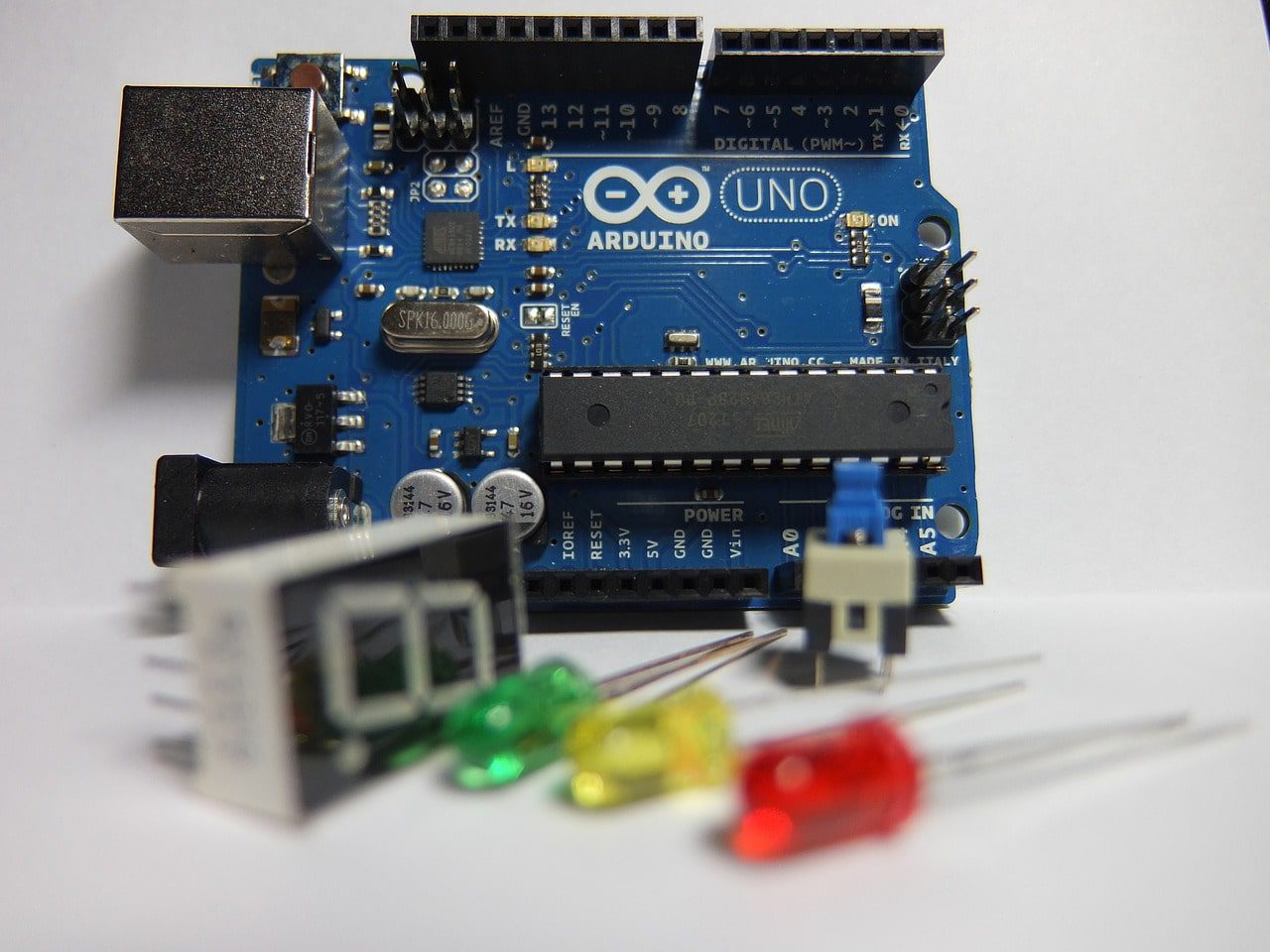

Tiny Proximity Sensors that detect objects are changing how things are found in industries from factories, to gadgets people use. These sensors can tell if something is there or not without touching it. Then they turn that information into a signal. Because they can be used in types of sensor applications they make things work better and faster. There are kinds of these sensors each with its own way of working and special features, especially useful for finding non-magnetic metals and more.

This article talks about the ideas driving forward these sensors comparing the different technologies that make them work. By explaining what to look for when choosing one and showing where they can be used people will learn how important these sensors are, in today’s technology. Looking into the future the discussion will also talk about what might happen with this kind of sensor technology.

Technological Innovation behind Tiny Proximity Sensors

Tiny proximity sensors have been advancing quickly due, to breakthroughs that improve how they work and their versatility in different sectors. These sensors play a role in a range of uses from industrial automation to advanced military setups all thanks, to their improved functions and abilities.

Smarter Sensor Technologies

- IO-Link Functionality: Contemporary small proximity sensors now utilize IO-Link technology enabling real time monitoring of conditions and predictive maintenance. This advanced capability allows sensors to share information, on their status and surroundings making it easier to perform maintenance tasks that avoid downtimes.

- Integration of IoT and Wireless Connectivity: The use of IOT technologies, in small proximity sensors enables data transfer and remote supervision. This connectivity facilitates integration, into systems improving operational efficiency and data availability.

Advanced Sensing Technologies

- Ultrasonic and Laser Rangefinder Technologies: These sensors use frequency waves and electromagnetic beams to detect objects. Ultrasonic sensors are not affected by the color or transparency of objects making them ideal, for environments whereas laser rangefinders provide measurements.

- Inductive and Capacitive Technologies: Inductive sensors work well in detecting metal items using induction while capacitive sensors have the ability to detect both non-metallic objects, such, as liquids and powders making them versatile, for a wide range of uses.

Enhanced Durability and Environmental Resistance

- Today’s sensors come with IP ratings that provide enhanced protection, against dust, water ingress and harsh conditions like exposure to cutting oils. This robust design boosts the longevity and reliability of sensors, in environments.

- The design modifications also incorporate durability, against temperatures, vibrations and harmful chemicals allowing these sensors to be suitable for applications in locations such, as mining sites and agricultural environments.

Miniaturization and Improved Performance

- Space-Saving Designs: The progress, in microelectronics has made it possible to shrink tiny proximity sensors making it easier to place them in spaces without compromising their effectiveness.

- High-Precision and Enhanced Sensitivity: Recent versions of tiny proximity sensors come with enhanced detection capabilities and quicker reaction speeds. These enhancements guarantee precision and effectiveness in a range of uses.

Application-Specific Innovations

- Military Applications: Sensors like the Cockpit-Selectable Height-of-Burst Sensor (C-HOBS) are designed to be reprogrammable to meet the needs of different military branches, enhancing versatility and functionality in defense applications.

- Partnerships for Enhanced Production: Collaboration with companies like Eaton Corporation facilitates the mass production of these sensors, ensuring availability and continued support for these technologies.

These innovations not only enhance the functionality of tiny proximity sensors but also expand their application scope, making them indispensable tools in modern technology. Through continuous improvement and adaptation, these sensors are set to play a pivotal role in the future of automation and smart technology.

Comparison of Different Tiny Proximity Sensor Technologies

Let’s compare some tiny proximity sensors

Ultrasonic Proximity Sensors

Ultrasonic proximity sensors operate using echolocation principles, similar to how bats navigate. These sensors emit ultrasonic pulses and measure the time taken for these pulses to reflect back from an object, enabling them to detect the presence or calculate the distance to an object.

Advantages:

- High accuracy and refresh rates make them suitable for dynamic environments.

- Insensitivity to object color and transparency allows versatility across various applications.

Disadvantages:

- Detection area may increase over time due to the spread of sound waves.

- Performance can be affected by changes in air temperature.

- Not suitable for underwater or vacuum environments due to reliance on air for sound transmission.

Photoelectric Proximity Sensors

Photoelectric sensors are widely utilized for detecting the presence or absence of objects using light beams. They are prevalent in industrial, residential, and commercial settings due to their reliability and long lifespan.

Advantages:

- Long product life cycles due to no moving parts.

- Capable of sensing a wide range of materials.

Disadvantages:

- Challenges with transparent objects or in watery conditions.

- Sensitivity to object color and reflectivity can lead to inconsistencies.

- Requires precise mounting and alignment to function effectively.

Laser Rangefinder Sensors

Laser rangefinder sensors use electromagnetic beams to detect objects, operating on principles similar to ultrasonic sensors but with light instead of sound.

Advantages:

- Long detection ranges and quick response times ideal for high-precision applications.

- Focused sensing area provides precise measurements.

Disadvantages:

- Higher cost compared to other sensor technologies.

- High power consumption and potential safety risks to eyes.

- Not effective for detecting water or glass, limiting some applications.

Inductive Sensors

Inductive sensors are specifically useful for detecting metallic objects. They detect changes in magnetic fields caused by metallic objects entering their range.

Advantages:

- Wide detection range from millimeters to meters.

- Extremely fast refresh rates and simple operation enhance their usability in industrial environments.

Disadvantages:

- Limited to detecting metallic objects, which may not be suitable for all applications.

- Susceptible to interference from external magnetic and electrical fields.

Each of these tiny proximity sensor technologies offers unique benefits and limitations, making them suitable for specific applications and environments. Understanding these characteristics helps in selecting the right sensor technology for specific needs in industrial automation, consumer electronics, and beyond.

Key Features to Consider When Selecting Tiny Proximity Sensors

These are some Key Features to Consider When Selecting Tiny Proximity Sensors:

Object Requirements

Understanding the specific requirements of the objects to be detected is crucial. Considerations include:

- Color: Some sensors may have difficulty detecting certain colors or transparent materials.

- Shape: The shape of the object can affect detection accuracy, especially if the sensor has a narrow sensing field.

- Material: Choose sensors based on the material of the object, whether it’s metallic or non-metalic, as this determines the type of sensor needed (inductive, capacitive, or magnetic).

Environment of Sensing

The environment where the sensor will operate can greatly influence its effectiveness:

- Cleanliness: Dust and debris can affect sensor accuracy, especially for optical types.

- Temperature: Extreme temperatures can impact sensor functionality, requiring sensors with specific temperature tolerances.

- Moisture: High humidity or exposure to liquids necessitates waterproof or resistant sensors.

Sensing Range and Distance

The distance from which a sensor can reliably detect objects is a key feature:

- Nominal Sensing Range (sn): Standard operating distance under ideal conditions.

- Effective Sensing Range (sr): Real-world operating distance, considering environmental factors.

- Useful Sensing Range (su): Range under varied temperatures and voltage fluctuations.

- Assured Sensing Range (sa): Guaranteed operational distance without failure.

- Hysteresis (H): Variation in detection distance as an object approaches and recedes.

Electrical System Compatibility

Ensure the sensor is compatible with the existing electrical system:

- Output Signal: Choose between AC or DC signals, with considerations for NPN or PNP outputs for DC systems.

- Supply Voltage: Match the sensor voltage requirements with your system, whether it’s AC110V, AC220V, DC12V, or DC24V.

Types of Proximity Sensors

Select the sensor type based on the application needs:

- Inductive: Best for metallic objects with a limited range.

- Capacitive: Good for detecting both metallic and non-metallic objects.

- Magnetic (Hall Effect): Ideal for detecting magnetic fields.

- Special: Designed for harsh environments or specific high-precision tasks.

Detection Range

Different sensors offer varying detection capabilities:

- Inductive: Range varies by the material of the object.

- Capacitive: Effective at short ranges.

- Magnetic: Detects magnetic signals exclusively.

- Special: Customized for specific industry needs.

Switching Frequency and Number of Contacts

- Switching Frequency: Determines how quickly the sensor can respond to object detection. Higher frequencies are suitable for high-speed applications.

- Number of Contacts: Choose from Normally Open (NO), Normally Closed (NC), or a combination based on circuit requirements.

Housing Design and Material

Select housing materials based on environmental exposure:

Materials: Options include stainless steel, nickel-plated brass, or various plastics like Crastin® or Ryton®, depending on the chemical and physical exposure.

Cable Material

Choose cable materials that can withstand environmental conditions:

- PVC: Offers standard durability against oils and abrasion.

- PUR: Resistant to oils, greases, and solvents, and maintains flexibility.

- Silicone: Best for extreme temperatures and moderately resistant to chemicals.

Mutual Interference

To avoid signal interference between sensors, maintain minimum distances as specified by the manufacturer, ensuring accurate and reliable operation.

Electrical Data and Connections

Understand the wiring requirements to ensure proper installation and functionality:

- DC Proximity Switches: Available in two-wire, three-wire, and four-wire configurations.

- AC Proximity Switches: Typically two-wire systems.

- Specialty Switches: Include options for safety-related applications or advanced networking capabilities like AS-Interface.

Selecting the right tiny proximity sensor involves careful consideration of these key features to ensure optimal performance and reliability in specific applications and environments.

Application Areas of Tiny Proximity Sensors

Tiny proximity sensors play a role, in industries, where they are used to improve accuracy, productivity and safety. Let’s explore how these sensors are utilized across a range of sectors;

Industrial Automation

In automation tiny proximity sensors play a role. They are used to detect metal objects through sensors or sense both non-metallic objects using capacitive sensors. This flexibility is key, for enhancing production efficiency and ensuring safety protocols.

Food & Beverage Industry

In the food and beverage sector, proximity sensors contribute to maintaining high standards of hygiene and efficiency. They are employed for tasks like level detection in liquids and position sensing in automated machinery, ensuring consistent product quality and safety.

Semiconductor Manufacturing

The precision required in semiconductor manufacturing makes tiny proximity sensors invaluable. They are used for the accurate positioning and detection of components, which is critical in the assembly of delicate semiconductor devices.

Building and Infrastructure

Tiny Proximity sensors find applications in building and facilities infrastructure, helping in the management of data and electrical systems. Their role in enhancing energy efficiency and optimizing space through intelligent automation solutions is increasingly recognized.

Transportation and Railways

In transportation, especially electric vehicles (EVs) and railway systems, tiny proximity sensors are used for positioning, level detection, and implementing safety systems. Their ability to provide precise measurements ensures the reliability and safety of transport systems.

Power and Renewable Energy

The power and renewables sector relies on proximity sensors for monitoring and controlling equipment. These sensors help in maintaining the efficiency and safety of power generation and distribution systems.

Water and Wastewater Management

Proximity sensors are vital in water and wastewater treatment facilities for tasks such as level detection, flow monitoring, and leak detection. They contribute significantly to the efficiency and reliability of water management systems.

Medical and Life Sciences

In medical and life science applications, tiny proximity sensors are used for precise positioning, monitoring, and control of medical equipment. Their accuracy and reliability support critical healthcare operations and research activities.

Oil, Gas, Mining, and Metals

The harsh environments of the oil, gas, mining, and metals industries demand robust sensor solutions. Proximity sensors are used here for equipment monitoring and safety systems, helping to prevent accidents and enhance operational efficiency.

Robotics

Robotics applications benefit greatly from tiny proximity sensors, especially in the precise movement and positioning of robotic arms and other components. These sensors are essential for the smooth operation of automated systems.

Security Systems

In security systems, proximity sensors detect the presence of intruders or unauthorized personnel, playing a crucial role in safeguarding premises.

Automotive Technologies

Tiny proximity sensors are also pivotal in automotive technologies, such as self-parking systems and anti-collision safety systems. They help vehicles detect obstacles, aiding in safer navigation and parking.

Specialized Industrial Applications

In specialized settings like welding fixtures and stamping dies, tiny proximity sensors provide critical feedback. They ensure the safety and accuracy of operations by detecting conditions like slag build-up or component misalignment.

These diverse applications underscore the versatility and importance of tiny proximity sensors across industries, highlighting their role in advancing technology and improving operational efficiencies in various settings.

Conclusion and Future Trends in Tiny Proximity Sensors

Throughout our exploration of tiny proximity sensors we have delved into their uses, technological advancements and important factors to consider when choosing and incorporating them. The progress we’ve talked about highlights the role these sensors play in improving accuracy, effectiveness and safety in a range of industries –, from making semiconductors to renewable energy, industrial automation and more. Their ongoing development assures us that they will continue to push boundaries and remain a tool for innovation and operational success.

Looking ahead the future of tiny proximity sensors suggests they will become more integrated with technology, smarter systems and will be present in all sectors seeking to utilize automated and intelligent solutions. The potential for these sensors to revolutionize processes, products and services is vast; offering opportunities for sustainability, safety enhancements and improved efficiency. Embracing these technologies not propels industries but also opens doors, to groundbreaking progress that will define the future of automation and technological advancement.