Remote humidity sensors have become tools, in industries offering real time monitoring and regulation of moisture levels in crucial settings. These sophisticated devices bring a host of advantages from safeguarding product quality and security to enhancing efficiency and cutting down expenses. By incorporating a remote humidity sensor companies can greatly enhance their effectiveness, dependability and overall output.

This article will delve into the benefits of utilizing remote humidity sensor, such as their capability to deliver the clock monitoring customizable notifications and user friendly interfaces. We will also touch upon how to choose the sensor for your specific requirements along with installation and configuration suggestions, for optimal performance. Furthermore we will explore applications and scenarios while also considering the future of humidity monitoring technology.

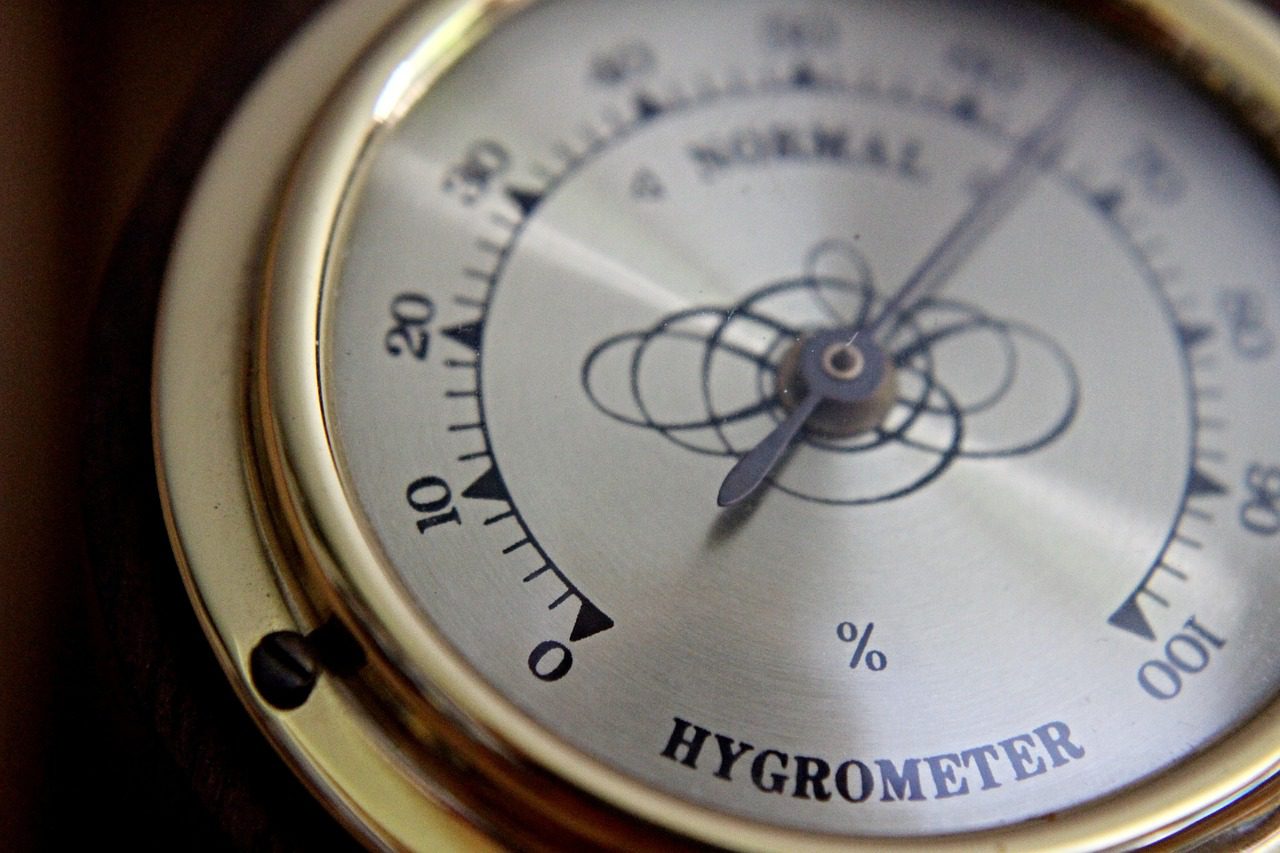

Understanding Remote Humidity Sensors

Remote humidity sensors are devices that electronically measure and communicate the level of moisture and temperature, in their surroundings. They offer readings through a signal specifying the humidity, which indicates the amount of moisture in the air compared to its maximum capacity, at a specific temperature. These sensors operate based on capacitance, resistance or thermal conductivity principles;

- Capacitive Sensors: These sensors utilize a metal oxide strip positioned between two electrodes. The electrical capacity of the metal oxide adjusts, in response, to the surrounding atmospheres humidity level.

- Resistive Sensors: The sensors use ions found in salts to gauge the resistance of atoms. When humidity levels fluctuate, the electrodes, on both sides of the salt medium experience changes, in resistance.

- Thermal Conductivity Sensors: The sensors track variations, in temperature to measure humidity levels. A pair of sensors generate currents according to the humidity content, in the air nearby.

Many humidity sensors rely on capacitive measurement technology to measure the moisture content, in the atmosphere. When moisture from the air accumulates on a film, which is not conductive it triggers fluctuations in voltage levels between two plates. This alteration is then translated into a reading of the airs humidity levels. Wireless remote humidity sensors are cloud based making it convenient for users to keep track of humidity levels in environments in laboratory settings using personal gadgets like smartphones and tablets. These sensors come in forms and sizes such as external options, standalone or interconnected configurations and with or without additional probes. Advanced humidity sensors support internet connectivity. Are suitable for use, in Internet of Things (IoT) setups, which enhances their functionality across a range of industries.

Top Benefits of Using Remote Humidity Sensors

Using remote humidity sensors comes with many benefits that help make operations more efficient maintain product quality and improve overall productivity. These innovative gadgets offer monitoring of humidity levels doing away with the need, for inspections and cutting down on labor expenses. Through alerts and updates companies can promptly address any deviations, in humidity levels thus averting harm to delicate products or machinery.

Key advantages of remote humidity sensors include:

- 24/7 Monitoring: Continuous monitoring of humidity levels, through sensors allows for 24/7 observation from any place, with internet connection guaranteeing that crucial environments stay within conditions.

- Customizable Alerts: People have the option to establish humidity limits, which will prompt notifications if the levels stray from the range. This enables actions and proactive choices to be made.

- Data Logging: Remote humidity sensors have the ability to record data continuously offering insights, for tracking patterns and identifying problems. This data can be utilized to enhance operations and anticipate challenges in the future.

- Regulatory Compliance: In industries, like pharmaceuticals and food manufacturing it is vital to uphold humidity levels to guarantee the quality and safety of products. Remote sensors streamline the inspection procedure ensuring adherence, to standards.

- Enhanced Efficiency: By automating humidity monitoring, businesses can focus on other critical areas of operation, improving overall productivity and efficiency.

Remote humidity sensors find applications across various industries, including:

- Laboratories: Maintaining precise humidity levels is essential for many laboratory processes and experiments.

- Pharmaceuticals: Humidity control is crucial for the production, storage, and transport of medications to maintain their efficacy and safety.

- Food Industry: Proper humidity levels prevent spoilage, extend shelf life, and ensure product quality.

- HVAC Systems: Remote sensors can optimize humidity levels in buildings, improving indoor air quality and system efficiency.

Selecting the Right Remote Humidity Sensor

When you’re selecting a humidity sensor it’s important to think about where and how you’ll use it well, as the need for reliable and easy to install monitoring solutions. Manufacturers are now creating sensors that use one wire for both transmitting data and supplying power, which helps reduce the number of wires needed and eliminates wall transformer units. These single wire sensors, like the D Wire Temperature and Humidity combo sensor offer installation, complicated wiring and reliability equal to or better than traditional analog sensors.

The Remote Terminal Unit (RTU) plays a role in a humidity monitoring system by taking input from analog or digital devices and using that data for monitoring tasks. When picking an RTU make sure it not meets your needs but also has features that align, with your long term goals. Look for quality tested RTUs housed in cases and customized to fit your systems specifications.

Essential features to consider when choosing a humidity monitoring system include:

- 24/7 system access

- Customized alert notifications

- Adequate sensor coverage

- Compatibility with analog or discrete humidity sensors

- Advanced battery support

- Integrated monitoring technologies

Disruptive Technologies has recently introduced a humidity sensor to its portfolio of innovative sensing solutions, offering a means to monitor relevant atmospheric humidity. Available in two variants for the European Union and the United States, this sensor boasts several unique selling points:

- Water and dust-resistant IP-68 rated design

- Battery-enabled lifetime of up to fifteen years

- Exceptional security

- Flexible integration into sophisticated IoT applications

When keeping an eye on the temperature and humidity, in storage it’s crucial to choose the kinds of remote sensors, for temperature and humidity. There are types of temperature sensors to consider:

- Resistance Temperature Detectors (RTDs)

- Thermistors (Negative Temperature Coefficient, or NTC)

- Thermocouples (such as Element-T sensor)

- Semiconductor-based sensors

Developing an effective temperature and humidity monitoring system involves answering questions about ideal conditions, sensor compatibility, and potential benefits from an actionable LabOps platform.

Installation and Setup Tips for Maximum Efficiency

When you’re setting up wall mounted RH transmitters make sure to select a spot that has air flow and reflects the humidity and temperature of the area you’re monitoring. Place the transmitter on a wall at a height of around 4 6 feet from the ground avoiding places, with much moisture, strong odors, vibrations or extreme temperatures.

For duct mount RH transmitters, follow these guidelines:

- Mount the transmitter so that the sensor probe is in the center of the duct.

- Ensure the transmitter is mounted away from fans, corners, heating and cooling coils, dampers, and other equipment that may affect the measurement of relative humidity.

- Check RH transmitters in a duct system annually.

When installing outdoor air mount RH transmitters:

- Choose a sheltered location, protected from rain.

- Ideally, install the transmitter on the north-side of the building (under an eave) to prevent sun-heated air from affecting the relative humidity of the sensor.

- Pay attention to the location of heat-generating condensing units and building vent & fan exhausts, as heated air and possible contaminants could influence the transmitter’s accuracy.

After you’ve connected the sensor and station give them about 15 minutes to sync up properly and establish a connection. Place the sensor on a wall facing north or in a spot to prevent overheating from sun exposure and make sure its mounted vertically for drainage. Remember that most sensors have a transmission range of, around 300 feet in spaces but this distance can be shortened by obstacles, like walls, floors, windows, trees or other items that might disrupt the signal.

Common Applications and Use Cases

Remote humidity sensors find applications across a wide range of industries, ensuring optimal environmental conditions and contributing to improved efficiency, safety, and quality control. Some common use cases include:

- Cold Storage Management: Remote humidity sensors are essential, for keeping the environment for goods like food, drinks and medications that are sensitive, to temperature. These sensors monitor humidity levels constantly to make sure rules are followed and equipment status checks are done automatically.

- HVAC Systems: In HVAC systems humidity sensors play a role, in managing mold growth and assessing airflow to optimize heating or cooling settings for areas. These sensors help in establishing secure and energy saving settings.

- Smart Buildings and Facilities Management: By offering information, on the moisture levels in rooms humidity sensors contribute to enhancing comfort levels, which can be adjusted precisely using the Building Management System (BMS). This functionality is applicable across a range of settings such as hospitals, medical facilities and educational institutions where ensuring temperature and humidity is crucial, for averting the transmission of illnesses and bacteria.

- Agriculture and Greenhouses: In the realm of agriculture remote humidity sensors play a role, by gauging moisture levels in the soil and surrounding areas to enhance plant growth and irrigation. Within greenhouses and grow houses these sensors are essential, for upholding conditions safeguarding plants from fluctuations that may lead to decreased yields.

- Manufacturing and Quality Control: In industries, like food processing, pharmaceuticals and microelectronics humidity sensors play a role in safeguarding products from moisture absorption and spoilage. Additionally they oversee drug storage facilities regulate moisture levels, in pharmaceutical and laboratory environments to prevent migration.

- Remote Monitoring and Intelligent Asset Management: Humidity sensors play a role, in monitoring and smart asset management scenarios. They can be installed on equipment like pumps, compressors, fans and data centers. This shift from preventive, to maintenance helps boost efficiency and minimize downtime effectively.

- Transportation and Logistics: Humidity sensors placed remotely are utilized in monitoring vehicles to maintain air and product temperatures regardless of external factors. This use case holds importance when it comes to transporting items and materials sensitive, to temperature fluctuations.

Monitoring and management (RMM) software is now widely used in a range of sectors such, as IT, hospitality, healthcare and smart cities. With advancements in technology operators can leverage visualization. Reporting features to extract valuable insights, from temperature and humidity data. This helps in making decisions and streamlining operations effectively.

Looking Ahead: The Future of Humidity Monitoring

The evolution of humidity sensors has made strides from early techniques such, as animal hair, paper coils and sling psychrometers. The introduction of the transistor played a role in the development of humidity sensors that gauge resistance ultimately leading to the pioneering HUMICAP sensor by Vaisala in 1973. This innovative capacitive humidity sensor employs a thin film polymer structure that interacts with water vapor in the atmosphere alongside two electrodes to detect alterations in capacitance.

HUMICAP sensors have been applied across sectors ranging from meteorology to life sciences wherever precise humidity monitoring is vital, for maintaining quality and comfort. When paired with top notch temperature sensors contemporary humidity gauges can compute humidity related parameters, including:

- Dew point

- Enthalpy

- Absolute humidity

- Parts per million (ppm)

Technology is progressing, bringing about solutions such, as Elemental Machines LabOps platform, which aims to simplify the monitoring of temperature and humidity. This system combines software and hardware components, integrates with systems and enables the creation of personalized dashboards for efficient monitoring purposes. With the growing use of devices and cloud based technologies the outlook for humidity monitoring appears bright promising precision, in data collection and timely insights to enhance operational efficiency across diverse sectors.

Conclusion

The use of remote humidity sensors has transformed the way companies oversee and manage conditions, across diverse sectors. By offering up to the minute data, notifications and user friendly interfaces these sophisticated devices empower businesses to streamline their operations safeguard product quality and boost efficiency. As technology advances the fusion of humidity sensors with platforms and cloud based solutions holds the promise of providing even more precise and actionable insights.

Opting for remote humidity monitoring systems is a move, for companies aiming to enhance their processes adhere to standards and elevate product standards. Equipped with top notch sensors and a comprehensive monitoring system organizations can fully leverage their operations potential by cutting costs reducing downtime and maintaining an edge in today’s data landscape.