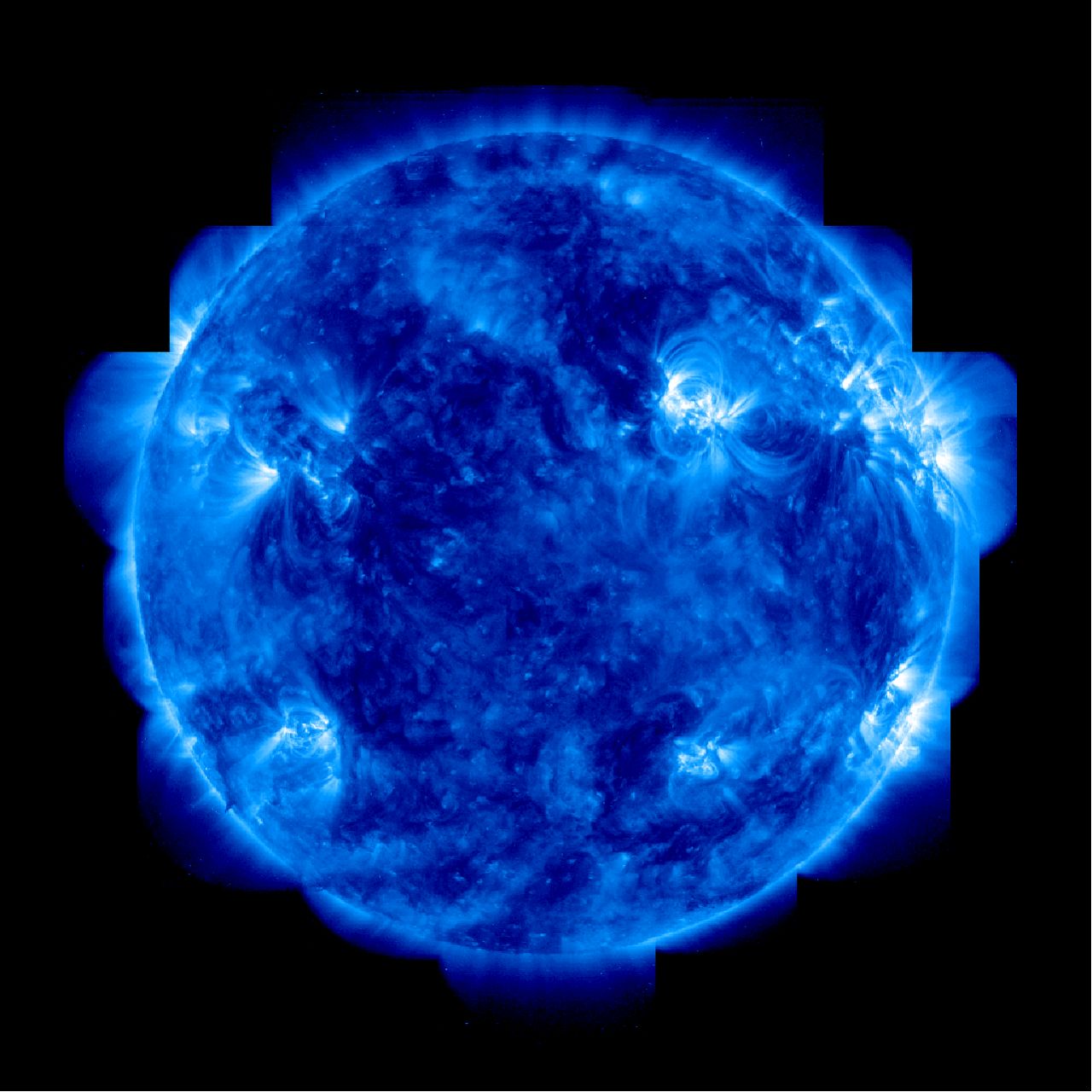

UV radiation is an occurrence that comes from the sun. While a considerable amount of UV radiation is absorbed by the Earth’s atmosphere and ozone layer some of it does manage to reach the surface. Moderate exposure, to UV radiation can actually be beneficial for health and ecosystems. However much UV exposure can be harmful. Even though we can’t see UV radiation with our eyes sensors specifically designed to detect it play a role, in monitoring its strength and evaluating the risks linked to UV exposure.

What is a UV Sensor?

A UV sensor often referred to as an Ultraviolet sensor is a device created to identify and gauge the strength of radiation. Its purpose is to act as a detector that can sense and measure the amount of UV radiation, in the surroundings. UV sensors play a role in monitoring UV radiation across sectors such, as industry, healthcare and the environment.

How Does a UV Sensor Work?

UV sensors work by detecting and measuring light. When ultraviolet light hits the surface of a UV sensor it excites electrons, within the sensor, which then produce signals that can be measured. There are two types of UV sensors; Photodiode UV sensors and Photocell UV sensors.

- Photodiode UV Sensors: These sensors gauge the currents magnitude produced when UV light strikes a photodiode. By evaluating the currents strength photodiode UV sensors can effectively determine the level of UV radiation.

- Photocell UV Sensors: These sensors detect alterations in resistance when they are exposed to UV light. By analyzing these changes photocell UV sensors are able to determine the strength of UV radiation.

UV sensors are used in areas such, as monitoring, measuring UV radiation doses sterilizing with UV light, medical devices, water treatment equipment and more.

Types of UV Sensors

Ultraviolet radiation can be categorized into three types depending on their wavelength ranges; UVA (Long wave Ultraviolet) UVB (Medium wave Ultraviolet) and UVC (Short wave Ultraviolet). Correspondingly UV sensors are classified into three types:

1. UVA Sensors

- Wavelength Range: UVA sensors are designed to detect ultraviolet radiation within the wavelength range of 320 to 400 nanometers.

- Applications: UVA sensors are primarily used for measuring UVA radiation in sunlight, as this wavelength range has relatively minor effects on the skin and eyes.

- Fields: UVA sensors find applications in environmental monitoring, smart home devices, UV protection products, and more.

2. UVB Sensors

- Wavelength Range: UVB sensors are specifically designed to detect UVB radiation within the wavelength range of 280 to 320 nanometers.

- Applications: UVB radiation has a significant impact on the skin, making these sensors commonly used to measure UVB radiation in sunlight and assess the level of UV danger.

- Fields: UVB sensors are utilized in medical devices, smart sunscreen products, UV indicators, and more.

3. UVC Sensors

- Wavelength Range: UVC sensors are designed to detect UVC radiation within the wavelength range of 100 to 280 nanometers.

- Applications: UVC radiation has germicidal properties, leading to the common use of UVC sensors in UV disinfection devices to ensure proper UV exposure.

- Fields: UVC sensors are employed in medical devices, water treatment equipment, air purification devices, and more.

Applications of UV Sensors

UV sensors play a vital role in a wide range of applications across various industries. Here are some notable applications of UV sensors:

1. Medical Treatment

Researchers have found that UV radiation, with a wavelength of 310nm significantly impacts skin color, metabolism and growth. Utilizing this wavelength range UV therapy has shown results in the treatment of conditions, like vitiligo polymorphous light eruption, chronic eczema and light sensitive itching rash. In procedures involving UV therapy it is essential to monitor the intensity of UV radiation. This is where UV sensors play a role.

2. Flame Detection

UV flame detectors are specifically created to identify fires by detecting the radiation that is produced when substances combust. These detectors are ideal, for areas where open flames are expected during a fire incident. They can be utilized in locations where there is flame radiation or in places where there isn’t a smoldering phase. UV flame detectors generally need UV sensors that are both resistant, to temperatures and highly sensitive.

3. Arc Detection

High voltage machinery might encounter arc discharges caused by insulation flaws, which emit radiation, including UV light. To assess the safety of voltage equipment UV sensors can identify the UV radiation produced during these arc discharges. Utilizing UV imaging is an approach, for detecting and precisely locating arc discharges. Nonetheless the faint nature of UV signals presents challenges in the detection procedure.

4. Banknote Recognition

UV recognition technology makes use of UV sensors to detect marks and anti-counterfeiting features on banknotes well as the way banknotes react to dullness. This technology plays a role, in identifying types of counterfeit bills like those that have been washed bleached or altered. UV sensors are utilized in devices such as ATM deposit recognition machines, currency counters and counterfeit detectors. By analyzing the absorption and reflection rates of UV light on paper compared to materials UV sensors enable the determination of banknote authenticity.

Apart from their use in detecting currency UV sensors also have applications, in weather stations, environmental monitoring systems, UV sterilization equipment and other fields where monitoring UV radiation’s necessary.

Installing a UV Sensor

Installing a UV sensor correctly is essential to obtain dependable measurements. Here are the important steps to follow when installing a UV sensor:

Choosing a Location

Choose a spot, at the measurement site that’s open and free from any obstructions to place the UV sensor. This will allow the sensor to receive UV radiation without any obstacles. It’s also crucial to make sure that the UV sensor stays in an area, throughout the day so that it can accurately measure UV levels in that location.

Determining the Installation Height

To ensure measurement results it is important to install UV sensors at specific heights. Take into account the design of the UV sensor and any environmental factors that might affect its performance, like buildings or vegetation. By installing the sensor at the height you can minimize the influence of these factors, on measurement accuracy.

Connecting the Cables

Make sure to follow the manufacturer instructions when connecting the power and signal lines of the UV sensor. It is important to ensure that the connections are secure to avoid any looseness or poor contact. Additionally try to minimize cable crossovers to prevent interference. If you are installing the sensor in an environment take steps to protect the cables from moisture.

Testing and Calibration

Upon completing the installation it is advisable to conduct testing and calibration in accordance, with the product manual. To ensure measurements it is recommended to calibrate the UV sensor as, per the manufacturer instructions. Should any problems arise it is advisable to reach out to support for assistance.

Conclusion

UV sensors play a role, in detecting and measuring radiation across various applications. They help monitor the intensity of UV rays ensuring the safety and effectiveness of processes and equipment related to UV. There are types of UV sensors each designed for specific ranges of wavelengths. These sensors find applications in treatments, flame and arc detection banknote recognition among others. It is crucial to install and calibrate UV sensors correctly to obtain measurements and reliable data. By utilizing UV sensors we can gain an understanding of risks associated with UV radiation contributing to enhanced safety and well-being, across different industries and environments.