The oil pressure sensor, in your car plays a role in keeping your engine healthy. It acts as the drivers eyes connecting with the oil pressure gauge on the dashboard to maintain oil pressure. This feature is essential because proper oil pressure ensures that the engines moving parts stay well lubricated reducing wear and guarding against engine issues or breakdowns.

In this article we will take a look, at the oil pressure sensor discussing its function and the importance of the oil pressure switch. We will also examine signs of sensor failure how to conduct tests on it steps for self-replacing it and selecting the oil pressure sensor for your vehicle.

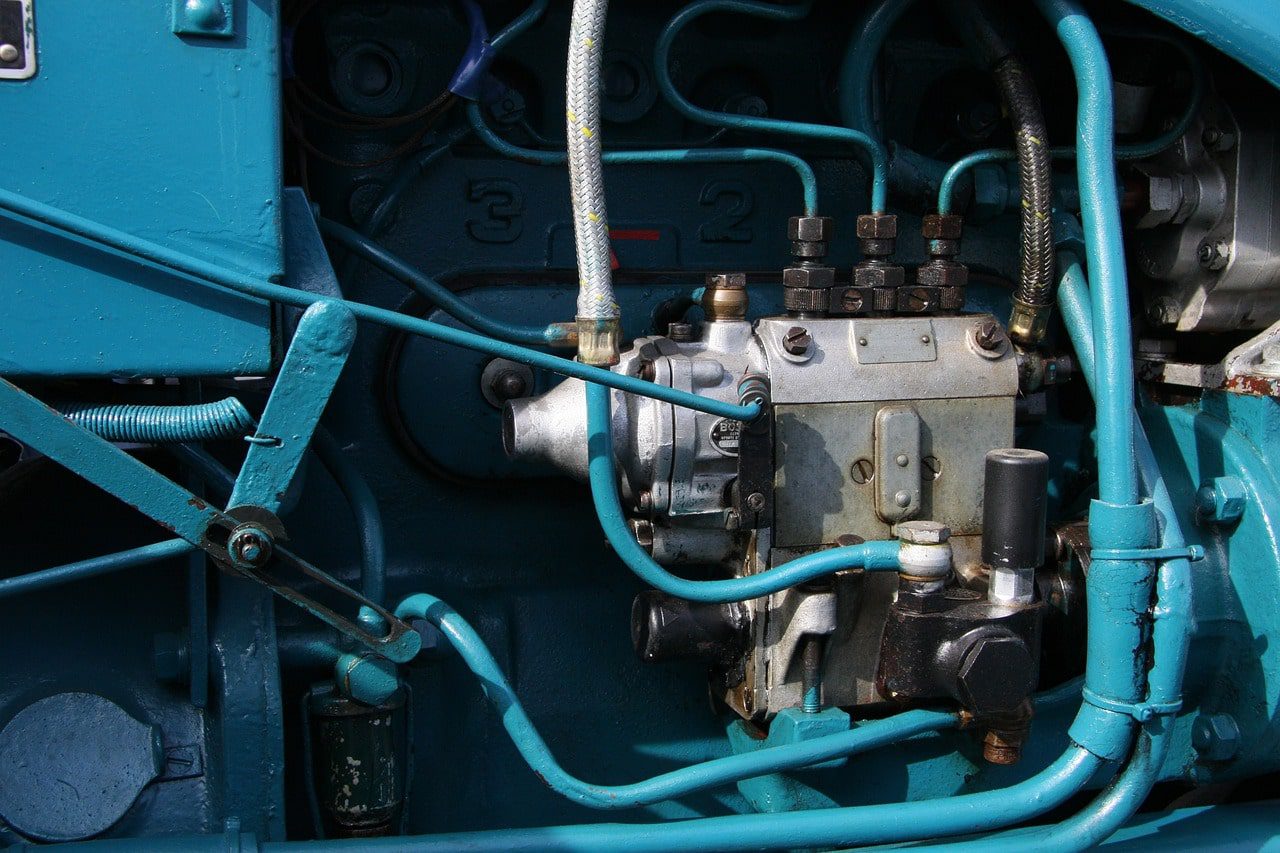

Understanding the Engine Oil Pressure Sensor

The engine oil pressure sensor is crucial for keeping track of and regulating the oil pressure levels. It’s responsible, for making sure that the engine components receive lubrication to protect them from wear and tear.

Function and Mechanism

- Monitoring Oil Pressure: The main role of the oil pressure sensor is to keep track of the oil pressure, in the engines lubrication system. It relies on a pressure component, like a diaphragm or strain gauge to identify fluctuations, in oil pressure.

- Signal Transmission: After checking the oil pressure the sensor transmits an analog voltage signal, to the engine control unit (ECU). The ECU then converts this signal into a format, for examination.

- ECU Analysis: The Electronic Control Unit (ECU) checks the signal using set limits to decide if the oil pressure is, at a level. If the pressure is below the range it activates a warning light, on the dashboard to notify the driver.

Design and Components

- Spring-Loaded Switch and Diaphragm: Most sensors feature a spring-loaded switch coupled with a diaphragm. This setup helps open or close the electrical circuit based on the oil pressure levels.

- Integrated Circuitry: Advanced sensors may also include integrated electronic circuitry and temperature sensors for enhanced functionality and signal conditioning.

Operational States

- Normally Open/Closed: The oil pressure switch can be in a normally open or closed state. It remains open when the car is off and closes when the oil pressure reaches the required level.

- Circuit Monitoring: The ECU continuously monitors the state of the circuit. A closed circuit indicates normal oil pressure, while an open circuit signals a drop in pressure, prompting immediate attention.

Location and Replacement

The oil pressure sensor is usually found on the engine block, oil pump or close, to the oil filter housing. Its convenient placement enables checks and replacements if needed.

When drivers grasp the function and purpose of the engine oil pressure sensor they can gain an understanding of how crucial this part is, in preserving their vehicles engine performance and effectiveness.

Signs of a Failing Oil Pressure Sensor

Recognizing the signs of a failing engine oil pressure sensor is crucial for maintaining the health and efficiency of your vehicle’s engine. Here are the key indicators that may suggest your oil pressure sensor is malfunctioning:

Malfunctioning Oil Pressure Gauge

One of the most immediate signs of an issue is an oil pressure gauge that either sticks at a high or low reading or fluctuates erratically. Under normal conditions, the gauge should provide a steady reading that corresponds with the engine’s RPM.

Illuminated Oil Pressure Warning Light

An illuminated oil pressure warning light on your dashboard is a direct signal from the oil pressure sensor. If this light activates while driving, it indicates that the sensor is detecting an oil pressure level outside the normal range, which could be either too low or falsely reported due to sensor failure.

Decreased Engine Performance or Efficiency

A failing oil pressure sensor can lead to noticeable decreases in engine performance and efficiency. This might manifest as reduced acceleration power, higher fuel consumption, or overall sluggishness of the vehicle.

Engine Noise or Vibrations

Inadequate lubrication due to incorrect oil pressure readings can cause the engine to make unusual noises or vibrate, especially at idle. These symptoms are often more noticeable during startup or when the engine is under strain.

Diagnostic Trouble Codes and Check Engine Light

When a modern car has a system and the oil pressure sensor malfunctions it will cause the check engine light to come on. Typically this situation is also marked by a diagnostic trouble code saved in the cars computer system signaling an issue, with the sensor.

Erratic Readings on Dashboard

If the oil gauge, on your cars dashboard consistently shows zero fluctuates unpredictably between these levels it likely means there are problems with the sensors. This inconsistent behavior could lead drivers to be uncertain, about the oil pressure situation.

Blinking Oil Pressure Warning Light

When the oil pressure warning light blinks, with a message indicating low engine oil levels it could mean there’s a problem with the sensor. This occasional blinking typically indicates that the sensor may not be accurately measuring and reporting oil pressure.

Being attentive to these signals allows drivers to tackle sensor problems before they escalate into engine issues. Identifying these concerns on and maintaining your vehicle promptly are crucial, for keeping it running effectively.

How to Test Your Engine Oil Pressure Sensor

Testing the engine oil pressure sensor is a vital procedure to ensure your vehicle’s engine operates efficiently and safely. Here’s a step-by-step guide on how to conduct this test effectively:

Step 1: Prepare Your Testing Equipment

First, gather all necessary tools including a multimeter, an oil pressure gauge, and possibly an air pressure source like an air gun or bike pump. Ensure your multimeter is set to the correct settings—continuity and resistance—for the upcoming tests.

Step 2: Visual Inspection

Begin by visually inspecting all wiring and connections related to the oil pressure sensor. Look for any signs of wear, damage, or corrosion that could affect the sensor’s functionality.

Step 3: Check Continuity and Resistance

Let’s Check Continuity and Resistance:

Continuity Test:

- Set your multimeter to the continuity setting.

- Connect one probe to the sensor’s wire and the other to a known good ground.

- A beeping sound from the multimeter indicates good wire condition; no sound suggests a break in the wire which may need replacement.

Resistance Test:

- Switch the multimeter to measure resistance.

- Touch one probe to the sensor and the other to the ground.

- Compare the resistance reading to the manufacturer’s specifications. Deviations indicate a faulty sensor needing replacement.

Step 4: Simulate Oil Pressure

If you do not have a running engine available:

- Use compressed air to simulate oil pressure.

- Attach the air pressure source to the sensor.

- Observe the multimeter for any changes. If using a mechanical gauge, note the pressure readings.

Step 5: Check for Air Leaks

- Submerge the sensor in water if possible.

- Apply air pressure to the sensor.

- Watch for air bubbles or rising water levels, which indicate a leak in the sensor.

Step 6: Use Diagnostic Tools

If equipped, use a code reader or scan tool to check for any Diagnostic Trouble Codes (DTCs) related to the oil pressure sensor. These codes can provide specific insights into potential issues with the sensor system.

Step 7: Mechanical Oil Pressure Test

Before considering sensor replacement:

- Connect a mechanical oil pressure gauge directly to the engine.

- Start the engine and monitor the oil pressure.

- Compare the readings with standard values to determine if the issue lies with the sensor or elsewhere in the system.

By following these steps, you can thoroughly test your engine oil pressure sensor, ensuring it functions correctly and continues to provide reliable service. This proactive approach helps in maintaining optimal engine performance and preventing potential engine damage due to oil pressure issues.

Replacing Your Oil Pressure Sensor: DIY Guide

Replacing the oil pressure sensor on your vehicle is a task that can be accomplished with some basic mechanical skills and the right tools. Here’s a detailed guide to help you through the process:

Necessary Tools and Materials

To begin, ensure you have the following tools and materials ready:

- Socket set (including a 27mm deep socket and a 22mm socket)

- Ratchet

- Oil filter wrench

- Oil pan

- Funnel

- New oil pressure sensor

- Engine oil

- Oil filter

- Rubber piece or electrical tape

- New crush washer

Step-by-Step Replacement Process

Step-by-Step Replacement Process of engine oil pressure sensor:

1. Locate the Oil Pressure Sensor

The oil pressure sensor is typically found on the engine block, near the timing cover, or on the cylinder head. It can also be located close to the oil filter or the oil pump.

2. Prepare the Area

Before starting, make sure the vehicle is parked on a level surface and the engine is cool. Place an oil pan under the vehicle to catch any dripping oil.

3. Remove the Electrical Connector

Disconnect the electrical connector from the oil pressure sensor. This might require gently pulling or pressing a release tab depending on the connector type.

4. Unscrew the Old Sensor

Using the appropriate socket size, remove the old oil pressure sensor. For most vehicles, a 27mm socket is required. Ensure it’s a deep socket to accommodate the length of the sensor.

5. Prepare the New Sensor

Before installing the new sensor, wrap it with a rubber piece or electrical tape to protect the connection. Place a new crush washer on the threads to ensure a good seal.

6. Install the New Sensor

Hand-thread the new oil pressure sensor into the opening to avoid cross-threading. Once in place, tighten the sensor with a wrench, being careful not to overtighten and damage the sensor.

7. Reconnect the Electrical Connector

Snap the wiring harness back into place on the new sensor.

8. Refill Oil

If oil was lost during the sensor replacement, use a funnel to refill the engine with the recommended type and amount of oil.

9. Check for Leaks

Start the engine and visually inspect the area around the new sensor for any leaks. Ensure that the oil pressure gauge on the dashboard is reading correctly.

10. Clear Engine Codes

Use a scan tool to clear any engine codes that may have been triggered due to the old faulty sensor.

Final Checks

After completing these steps, monitor the oil pressure gauge to ensure it maintains consistent pressure. Keep an eye out for any warning lights on the dashboard.

By following these detailed steps, you can successfully replace the oil pressure sensor in your vehicle, helping to maintain its engine health and performance.

Selecting the Right Oil Pressure Sensor for Your Vehicle

When choosing the oil pressure sensor, for your car it’s crucial to take into account factors to guarantee compatibility, longevity and effectiveness. Here are the primary elements to remember;

Compatibility with Your Vehicle

Make sure to check if the oil pressure sensor is compatible, with the make and model of your vehicle. This step is crucial to ensure that the sensor works properly and gives readings. Different vehicles may need types of sensors based on their engine designs.

Sensor Type

Choose between mechanical and electronic sensors based on your preference and vehicle requirements:

- Mechanical Sensors: These use a physical diaphragm to measure pressure. They are generally robust and provide reliable mechanical readings.

- Electronic Sensors: These sensors use a voltage divider to measure pressure and are typically more sensitive, providing digital readings for more precise monitoring.

Sensor Specifications

Pay attention to the following specifications to find a sensor that suits your vehicle’s needs:

- Pressure Range: Ensure the sensor’s pressure range matches or exceeds your vehicle’s operating pressure requirements.

- Port Size and Thread Type: The sensor must physically fit your vehicle, so check the port size and thread type against your vehicle’s specifications.

- High-Temperature Resistance and Durability: Opt for sensors designed to withstand high temperatures and are durable for long-lasting performance.

Performance Factors

Consider these performance-related factors for optimal functionality:

- Accuracy and Response Time: High accuracy and quick response time are crucial for real-time oil pressure monitoring, which can be critical in preventing engine damage.

- Warranty: Look for products with extended warranty periods for added assurance. For example, United Motor Products offers a five-year or fifty thousand mile warranty, which is significantly more extensive than the standard one-year or thirty-six thousand mile warranty provided by other manufacturers.

Cost Considerations

The prices of oil pressure sensors can range from $10 to, than $100 with the cost typically indicating the quality and features of the sensor. Some brands, such as Standard Motor Products (SMP) and Duralast, provide budget choices while WVE by Intermotor is recognized for its emphasis, on durability and top notch performance.

Troubleshooting with Error Codes

Make sure to know the diagnostic trouble codes associated with oil pressure sensors, like Code P0520, which signals problems, with the sensor or its wiring. Familiarity, with these codes can assist in diagnosing and upkeeping the sensor.

By taking these aspects into account you can pick an oil pressure sensor that guarantees dependability and effectiveness improving your vehicles performance and durability.

Conclusion

Throughout our investigation, into the engine oil pressure sensor we’ve discovered how crucial it is in the engine system of a vehicle. By monitoring oil pressure levels and alerting drivers to issues via the dashboard this component plays a role in safeguarding the health and efficiency of the engine. Its proper operation ensures that moving parts receive lubrication preventing wear and potential damage to the engine. Additionally recognizing signs of a malfunctioning sensor and knowing how to test and replace it empowers car owners to take knowledgeable actions to uphold or restore engine performance.

The process of identifying symptoms of sensor failure and choosing a replacement highlights the significance of vehicle maintenance. By following recommended guidelines drivers can significantly reduce the risks associated with engine damage caused by oil pressure. Ultimately maintaining your vehicles engine health relies on attention to details like the oil pressure sensor. Considering its impact drivers are advised to stay alert and proactive in their vehicle care routines ensuring their vehicle remains in shape, for future journeys.