The turbine speed sensor, also referred to as the input/turbine speed sensor holds importance in sectors such, as power generation, aerospace and automotive. This piece explores the functions of a turbine speed sensor, its operational mechanism and the possible challenges it might encounter in functioning.

Primary Function of a Turbine Speed Sensor

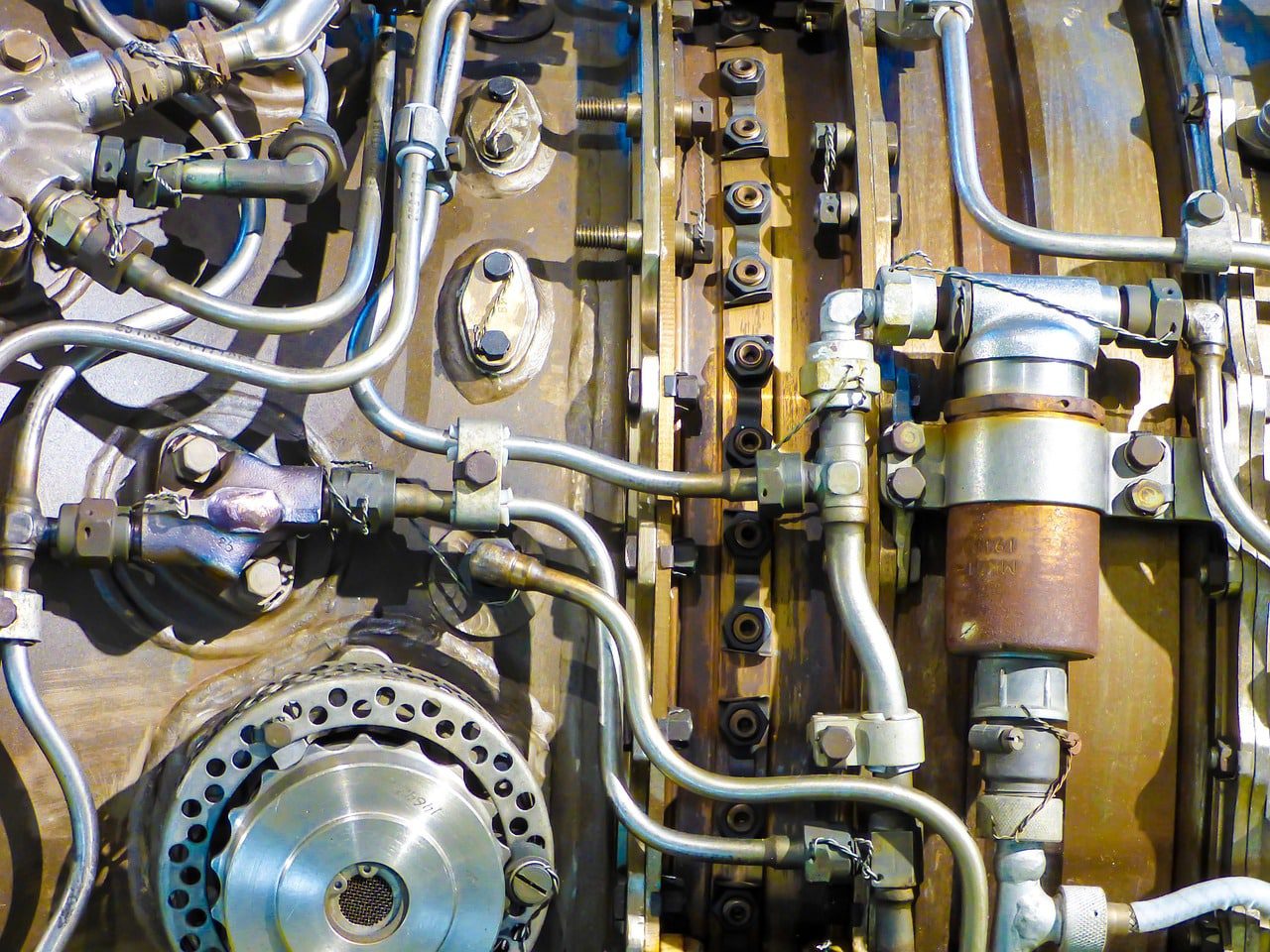

A turbine speed sensor is a device that electronically measures how a turbine rotates. Usually placed above the turbine shaft its main role is to give updates on the turbines speed.

This data plays a role, in overseeing and managing the turbines functions guaranteeing it runs at effective speeds. Additionally it assists in diagnosing issues and carrying out maintenance tasks.

The Working Principle of a Turbine Speed Sensor

The turbine speed sensor works by gauging how the turbine shaft rotates. The distance between the sensor and the shaft plays a role in how the sensor functions. This distance creates a signal known as ‘gap voltage,’ which is utilized by the sensor to determine the turbines speed.

To ensure readings the speed sensor must be adjusted correctly. Incorrect settings could lead to revolutions per minute (RPM) readings. The RPM information is then transmitted to the control panel providing operators with insights, into the turbines speed.

If the turbine is connected to a power grid its RPM will fluctuate based on grid conditions. However when operating independently (islanded) the turbines RPM remains constant.

The Importance of Correct Sensor Placement

The position of the speed sensor plays a role, in its operation. Usually it is installed above the turbine shaft. Setting the gap between the sensor and the shaft accurately referred to as ‘gap voltage’ is essential, for optimal sensor performance. Improper positioning may lead to data readings. Could potentially harm the turbine.

Turbine Speed Sensor Types

There are several types of turbine speed sensors, each with their unique applications and advantages. Some common types include:

- Tachometer: Either sensed off the turbine governor and shown with the appropriate step-down ratio, or electronic ones that comprise a disk with peripheral holes read by a light sensor.

- Torsion meters: Attached to the output shaft and measure both rotational speed and torque on the shaft.

- Magnetic pickups: Used in steam turbines to detect the speed of the turbine’s rotor.

Advanced Speed Sensors in "Wind Robots"

The use of turbine speed sensors, in energy in wind turbines showcases innovative applications. These turbines, also known as “wind robots ” utilize sensors to optimize their operations.

In wind turbines an anemometer gauges wind speed while a wind vane identifies wind direction. This information is then relayed to the controller, which adjusts blade pitch and rotor alignment based on the wind conditions. Turbines employ sensors to track their performance and monitor parameters such, as rotational speed.

Troubleshooting a Turbine Speed Sensor

The operation of a turbine speed sensor may be influenced by factors. In cases where the measured speed doesn’t match the expected speed it could trigger error codes like P0715. To address this problem it is advisable to begin by examining the sensor itself as its wiring, connections and adjacent components. The presence of rust or metallic fragments might impede the completion of a circuit thus impacting the sensors performance.

Conclusion

In conclusion turbine speed sensors are elements, in a range of industries. They have an impact, on maintaining the safety and effectiveness of turbine operations, which in turn enhances the system performance. Familiarizing oneself with their purpose, functionality and possible challenges can aid in their upkeep and problem solving resulting in improved efficiency and dependability.