Low current sensors play a role, in the world of devices ensuring their safe and efficient operation. These sensors are essential for detecting and measuring the current flowing through a conductor converting this information into data. Their importance lies in maintaining the integrity and reliability of devices making them a vital part of electronic system design and functionality.

With their measurement capabilities, low current sensors. Sometimes known as transducers. Have been widely embraced across various industries. This article will discuss the benefits of incorporating these sensors into devices explore their diverse applications, in different sectors and shed light on emerging trends and technological advancements. The process of selecting the current sensor to enhance device performance will also be examined to provide a comprehensive understanding of this critical technology.

Understanding Low Current Sensors

Low current sensors play a role, in ensuring the efficiency and safety of electronic devices. They need to have power consumption and a compact design to function effectively. These sensors are essential for measuring and monitoring amounts of current which is vital for assessing, managing and diagnosing the performance of electronic systems. Designers encounter obstacles when it comes to measuring current requiring a thorough understanding of the complexities involved. This includes taking into account factors such, as the sensors size, power needs and the specific electrical conditions it operates in.

The foundation of low current sensor technology rests on various physical principles, each offering unique advantages and considerations:

- Ohm’s Law-based Current Sensing: Drawing on the connection, among voltage, current and resistance it provides an dependable solution. Shunt resistors, widely used in this context generate a voltage decrease that corresponds to the passing, through them facilitating measurements.

- Faraday’s Law of Induction-based Sensing and Magnetic Field Sensors: These sensor, like transformers (CTs) and Rogowski coils perform well in systems that measure AC currents. CTs utilize the field produced by flow whereas Rogowski coils are known for measuring AC or fast current pulses despite their reduced sensitivity because they lack a high permeability magnetic core.

- Optical and Magnetic Sensing Technologies: Advanced sensing techniques include Hall effect sensors, Fluxgate sensors and Fiber optic current sensors. Hall effect sensors can measure the field without energy loss, for AC, DC. Pulsating current. Fluxgate sensors use a core to concentrate the field for precise AC or DC current measurement. Meanwhile Fiber optic sensors use an interferometer to detect light phase changes influenced by a field ensuring sensitivity and accuracy.

Selecting the right low current sensor involves a careful analysis of several factors:

- Current Type and Range: Determines the suitability of a sensor, whether for low-level DC, high-frequency AC, or transient currents.

- Accuracy and Sensitivity: Critical for applications requiring precise current measurement, influencing the choice between technologies like shunt resistors, Hall effect sensors, or more advanced magnetic and optical sensors.

- Bandwidth and Environmental Factors: The sensor’s ability to accurately measure over a wide range of frequencies and in varying environmental conditions.

- Size, Isolation, and Power Supply Requirements: Compact sensors with integrated isolation features are preferred for space-constrained applications, while power supply considerations impact the overall system design.

- Cost and Performance Needs: Balancing the cost against the required performance level, with considerations for error characteristics, thermal performance, and long-term reliability.

In summary low current sensors play a role, in today’s electronics greatly improving the efficiency, safety and dependability of systems, in industrial and consumer electronics industries. Familiarizing oneself with the concepts, variations and factors to consider when choosing current sensors empowers designers to incorporate these vital elements efficiently thereby boosting device functionality and user protection.

Key Advantages of Low Current Sensors in Electronics

Low current sensors like the ones provided by companies such, as Infineon, Aceinna and J&D have become essential in the world of devices in industrial settings. These sensors are highly valued for their precision, energy efficiency and reliable operation in conditions. In this discussion we delve into the benefits that highlight the role of low current sensors, in electronics.

High Accuracy and Robust Performance:

Infineons low current sensors are designed to provide precision making them perfect, for situations that demand current measurement. This accuracy remains consistent in industrial settings guaranteeing dependable performance, in challenging conditions.

Aceinnas AMR based isolated current sensors excel in their DC accuracy bandwidth and rapid output step response. These qualities make them well suited for applications that need accurate current measurements.

Versatility and Suitability for Various Applications:

Low current sensors come in packages and interfaces making them suitable, for an array of industrial uses. This flexibility means that no matter the projects needs there’s likely a sensor that meets the criteria.

Their crucial function in enhancing power efficiency and accurately sensing open loop current in motor drives in high temperature conditions (up to 105°C) showcases their versatility and effectiveness, across environments.

Advanced Features Meeting Industry 4.0 Demands:

Advancements, in technology for Industry 4.0 require devices to be more precise and efficient. Cutting edge low current sensors have been designed to fulfill these requirements providing improved accuracy across temperature conditions.

The IPCS current sensor series by J&D showcases creativity through its precision, energy efficiency and ability to measure DC, AC. Pulsed currents non intrusively and in isolation. These attributes play a role, in shaping the future of energy power electronic systems.

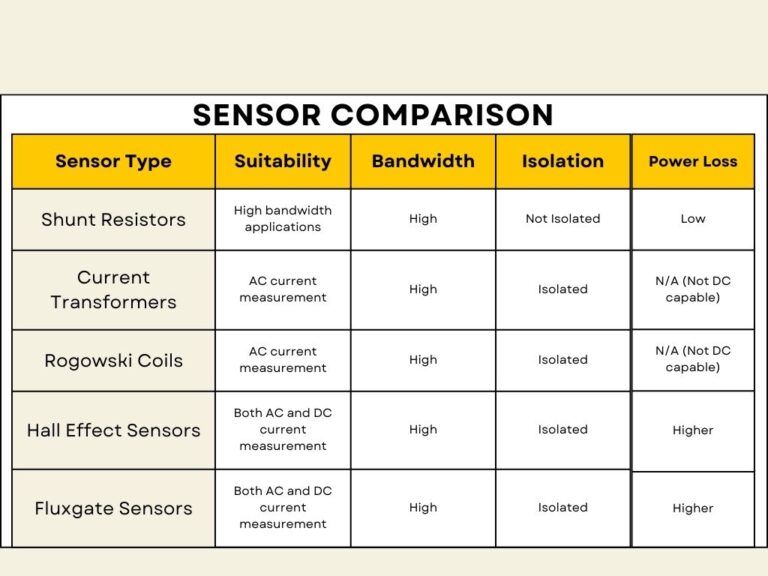

Sensor Comparison:

This comparison showcases the capabilities and tradeoffs linked to kinds of low current sensors. The sensor choice relies on the needs of the application, including the type, for measurement, isolation necessity, bandwidth requirements and acceptable power loss levels. Low current sensors provide increased precision, superior resolution and reduced power usage when compared to sensors. This makes them well suited for an array of applications, like battery management systems monitoring power supplies, industrial automation and control, test and measurement tools as consumer electronics.

Applications Across Industries

Low current sensors, with output are crucial in industries supporting the safety, effectiveness and dependability of many applications. Their flexibility and accuracy are vital in today’s technology and industrial processes. These sensors have a range of uses from consumer electronics, to intricate industrial setups.

Industrial and Automation:

- Motor Control and Drives: Accurate measurement of current is essential, for ensuring motors perform optimally. Are adequately protected. Utilizing sensors allows for precise adjustment of motor functions ultimately improving efficiency and extending their lifespan.

- Power Management: In environments efficiently controlling power usage can result in financial savings. Utilizing sensors offers precise information, for overseeing and enhancing power consumption.

- Automation Systems: In automation systems it’s crucial to have reliability and accuracy. Using sensors is key, to ensuring the smooth operation of these systems by offering precise current measurements. This precision is vital, for managing and troubleshooting loads effectively.

Energy and Infrastructure:

- Renewable Energy Systems: As the global shift, towards energy sources progresses the importance of low current sensors in solar panels and wind turbines grows significantly. These sensors are responsible, for overseeing the functionality and effectiveness of these systems to guarantee energy output.

- Battery Management Systems: In the realm of cars and handheld gadgets maintaining battery health is crucial. The use of sensors is vital, for monitoring charging processes and overall battery condition ultimately enhancing both battery lifespan and performance.

- Power Systems and Grid Monitoring: The stability of power grids depends on monitoring the flow of current. Sensors designed to detect currents play a role, in ensuring reliable protection, against overcurrent and effective energy management, which helps prevent power outages and maintain a consistent power supply.

Consumer and Commercial Applications:

- Consumer Electronics: In devices such as smartphones, laptops, and tablets, low current sensors are essential for power supply monitoring and enhancing battery efficiency, thereby improving user experience.

- Commercial Appliances: Safety features in commercial appliances, including cut-off mechanisms and surge protection, rely on specialized current sensors. These sensors ensure the appliances operate safely, preventing accidents and equipment damage.

- Test and Measurement Equipment: For engineers and technicians, accuracy is non-negotiable. Low current sensors in test equipment provide the precision needed for reliable diagnostics and research.

In scenarios, like industrial or consumer use the selection of a low current sensor is based on specific needs such as the type and range of current, accuracy, bandwidth and environmental conditions. This customized strategy guarantees that whether it’s for overseeing a panels efficiency guaranteeing the safety of devices or enhancing an electric vehicles battery performance low current sensors play a crucial role in advancing and ensuring the dependability of technology, in diverse sectors.

Emerging Trends and Technological Advancements

In the rapidly evolving landscape of electronic devices, emerging trends and technological advancements in low current sensors are setting new standards in efficiency, accuracy, and application versatility. Key developments include:

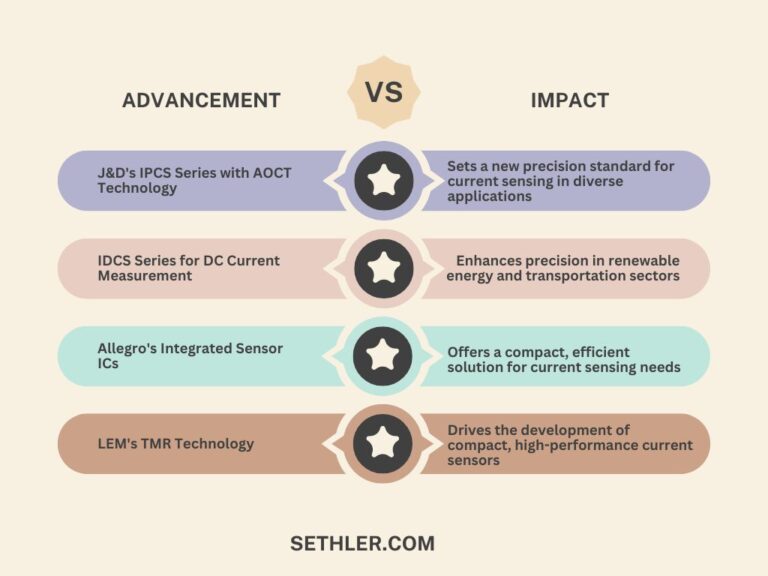

Innovative Technologies and Series:

- J&D’s IPCS Current Sensor Series: Utilizing AOCT technology inspired by DC metering design, the IPCS series offers unparalleled precision for non-intrusive and isolated measurement of DC, AC, and pulsed currents, catering to a nominal range of 100 A to 800 A.

- IDCS DC Current Sensors: These cost-effective sensors are pivotal in measuring DC current in industrial environments, especially in renewable energy or transportation, highlighting their crucial role in precision current measurements.

- Allegro Current Sensor IC Family: Allegro integrates a monolithic linear Hall-effect sensor with a low-resistance primary current conduction path, encapsulated in a single overmolded package for enhanced performance.

Strategic Partnerships and Design Innovations:

- LEM and TDK Partnership: This collaboration aims to redefine ICS performance standards for applications such as OBCs and solar inverters, leveraging TMR technology for improved speed and accuracy with reduced power consumption.

- TMR Technology in LEM’s ICSes: Demonstrates superior speed and accuracy, addressing the ‘smaller, smarter, cheaper’ device challenge with lower power consumption.

Focus on Efficiency and System Protection:

- Increasing System Voltage: A move towards higher system voltages is instrumental in reducing I2R losses, significantly enhancing system efficiency.

- Enhancing System Protection: Ensuring the system’s integrity, especially during events outside the safe operating area, is crucial to protect semiconductors and sensitive devices from damage.

- Enabling Telemetry Monitoring: This technology is pivotal for tracking energy consumption levels and facilitating predictive maintenance, a testament to the evolving landscape of current sensing technologies.

Technological Advancements and Their Impacts:

The progress highlights a change, towards dependable and adaptable current sensing options in line with the wider goals of worldwide decarbonization and electrification. With the evolution of the electronics industry incorporating these state of the art technologies into low current sensors is set to have a crucial impact, on shaping upcoming innovations and uses.

Selecting the Right Low Current Sensor

Selecting the right low current sensor for electronic devices involves a detailed evaluation of several key parameters to ensure optimal performance, efficiency, and reliability. Engineers and designers must consider the following aspects:

Current Sensor Technology Options:

- Current Sensing Resistors: Offer simplicity and are ideal for applications requiring high bandwidth.

- Hall Effect Sensors: Provide versatility for measuring AC, DC, or pulsating currents with minimal power loss.

- Inductive Sensors: Suitable for AC current measurements, leveraging magnetic fields generated by current flow.

- Magnetoresistive Sensors: Known for their high sensitivity and accuracy, making them suitable for precise current measurements.

Key Specifications to Consider:

- Measuring Range and Input Voltage: Essential to match the sensor with the current levels and voltages in the application.

- Frequency Range: Determines the sensor’s ability to accurately measure currents at different frequencies.

- Response Time and Isolation Voltage: Critical for applications requiring quick reaction times and electrical isolation for safety.

- Accuracy and Operating Temperature: High accuracy is vital for critical applications, while the operating temperature range ensures reliability under varying environmental conditions.

Mounting, Configuration, and Additional Features:

- Mounting and Configuration: Options include panel mount, SMD, clamp or bolt-on sensors, and PCB-mounted sensors. The choice depends on the device’s design constraints and installation requirements.

- Loop Type: Open loop sensors are generally simpler and less expensive, while closed loop sensors offer higher accuracy and stability.

- Features: Considerations include whether the sensor has an isolated tip, is designed for high voltage applications, or is intrinsically safe.

When it comes to designing inverters using SiC MOSFET modules keeping power consumption low and the size compact is crucial. Therefore choosing a sensor that meets these design standards involves examining the sensors power needs, output options and the specific requirements of the application. For example self-powered low current sensors may be favored for their efficiency while analog voltage signals or frequency modulated outputs could be chosen based on the inverters control system needs.

In essence selecting the right low current sensor involves finding a balance, between technical specifications, application demands and cost factors. It’s important to ensure compatibility, with the devices parameters and environmental conditions to achieve the desired performance and reliability.

Conclusion

Throughout the exploration of low current sensors, in electronic devices it’s clear that these components play a crucial role in modern electronics providing exceptional precision, reliability and efficiency for a wide range of uses. They enhance safety and performance in consumer electronics while also fueling advancements in energy and automotive sectors. The detailed examination of sensor technologies along with discussions on selection criteria and emerging trends emphasizes the importance of selecting the sensor to meet todays complex technological needs.

As the electronics industry progresses the significance of sensors in achieving higher levels of accuracy, efficiency and sustainability grows. This technology has implications that go beyond applications, impacting decarbonization goals and the advancement of Industry 4.0. With a focus on innovations and opportunities for exploration it’s evident that low current sensors will continue to drive technological progress across various industries while enhancing the quality of electronic devices essential, to modern society.